- Your Choise : Our Commitment

- +(66)9 5669 5654

- +(66)9 5669 5456

- ahaircomp@gmail.com

ผลิตภัณฑ์

Portable Screw Air Compressor

September 2, 2017

Variable Speed Screw Air Compressor

September 2, 2017Servo Inverter Screw Air Compressor

Features of AirHorse Servo Variable Speed Drive Screw Air Compressor

To determine whether an air compressor energy-saving,usually check “Specific

power”(input power ÷ Displacement per minute),That is ,under the same

displacement. The lower input power,the better specific power.

Features of AirHorse Servo Variable Speed Drive Screw Air Compressor

To determine whether an air compressor energy-saving,usually check “Specific

power”(input power ÷ Displacement per minute),That is ,under the same

displacement. The lower input power,the better specific power. AirHorse

Servo-inverter compressor is saving users’valuable energy by a significant

reduction in the specific power. Start small impact

Smooth soft start,Maximum starting current is within 1.6 times the rated

current,Compare to Frequency start which is usually maximum startingCurrent is 6

times.AirHorse serve inverter compressor decreased much Starting inrush

current,Reducing the share of transformer.make sure motor safety.

Air supply pressure stable

Improve the output frequency to Improve working efficiency.

Energy

Variable speed,Greatly improved the speed accuracy.

Can adaptive grid voltage

Over –modulation technique of inverter,it Sufficient torque output When the AC

voltage is slightly lower,Driving motor working well;If the AC voltage is

higher,It will not lead to a high voltage output of the motor.

Low noise

The inverter running according to air flow,there is no energy loss,the lower

operation frequency of motor,the smaller noise of rotation.Because inverter to

adjust the motor speed mode,without repeatedly loading,unloading,Reduce the

noise generated by the frequent loading and unloading,Continued

loading,Reducing the noise produced by unstable Barometric pressure. A small

amount of equipment maintenance

A small inverter starting current,Less than 2 times of the rated

current,without repeated loading and unloading,Inverter compressor

automatically adjust motor speed according to air consumption,The lower

operating time,the longer life of equipment,the smaller maintenance work.

Its easy to control under internet,automatic the production control.

Compared to V/F inverter technology,its higher efficient of low-frequency

operation,ster dynamic response,(So that the air compressor less load

fluctuations)More accurate speed control(Greatly enhance the accuracy of the

air comsumption). Saving power by factor compensation

Reactive power not only Increased line loss,but also heating Equipment,the

more important is leads to lower power factory by reducing active power

grid.Large amount of reactive power consumed in the circuit,Low equipment

efficiency,Wasted Our AirHorse servo inverter machine,As the role of the

inverter internal filter capacitor,Thereby reducing the reactive power

loss,increasing the active grid.

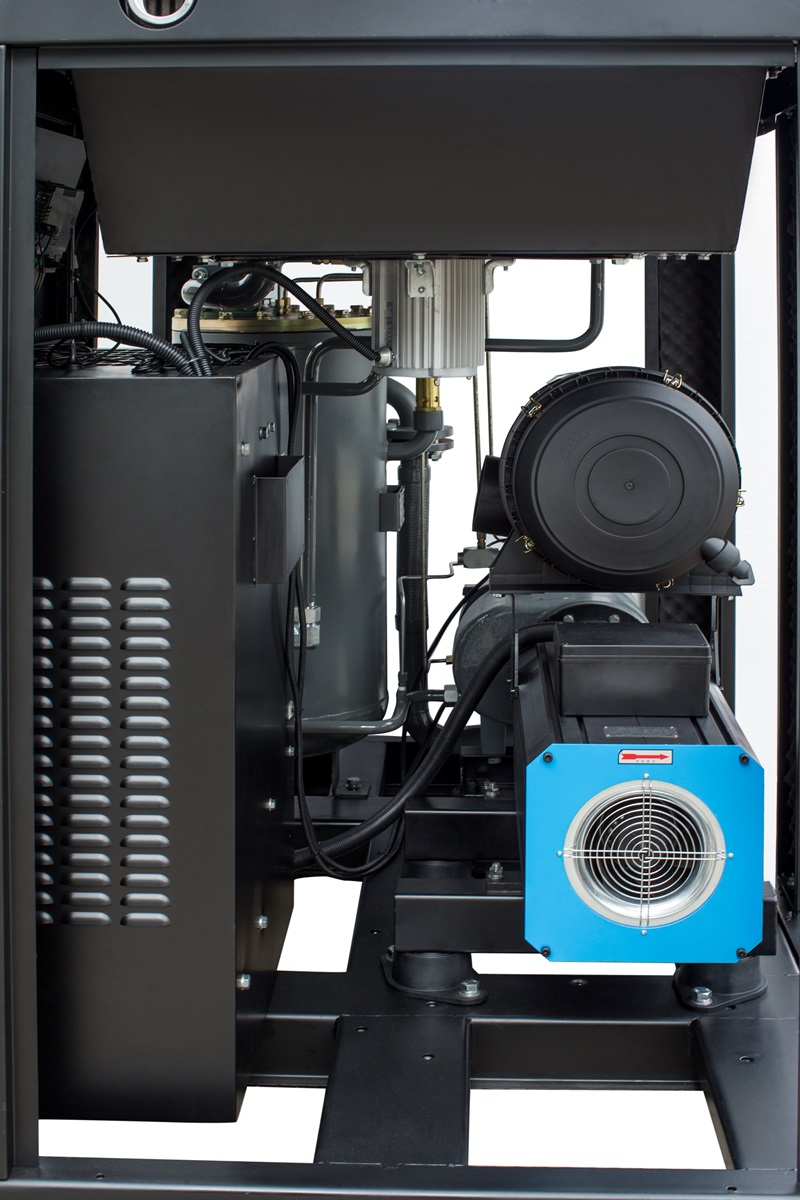

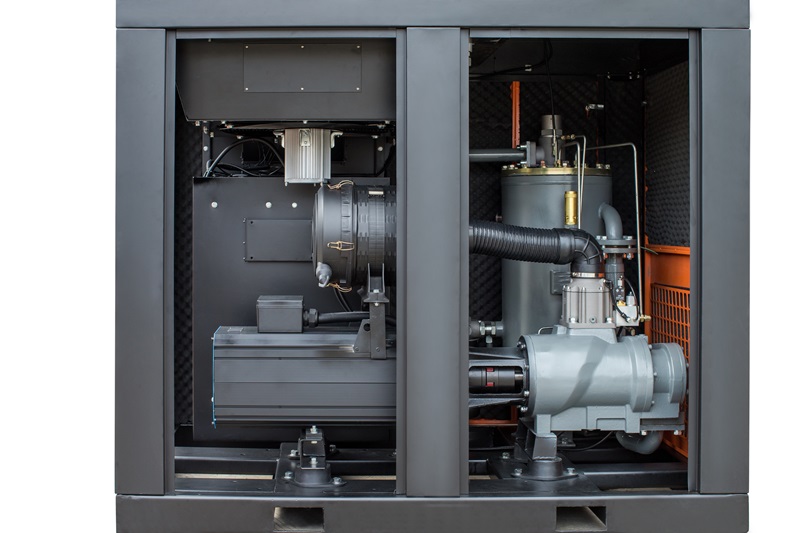

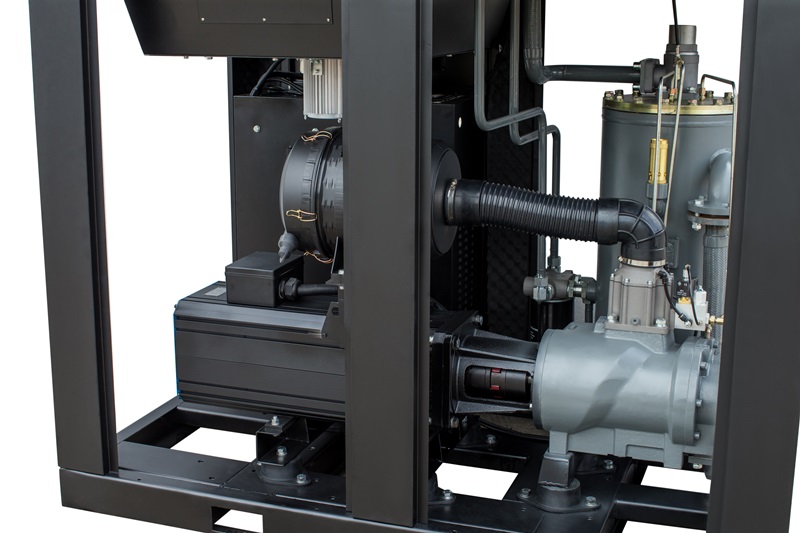

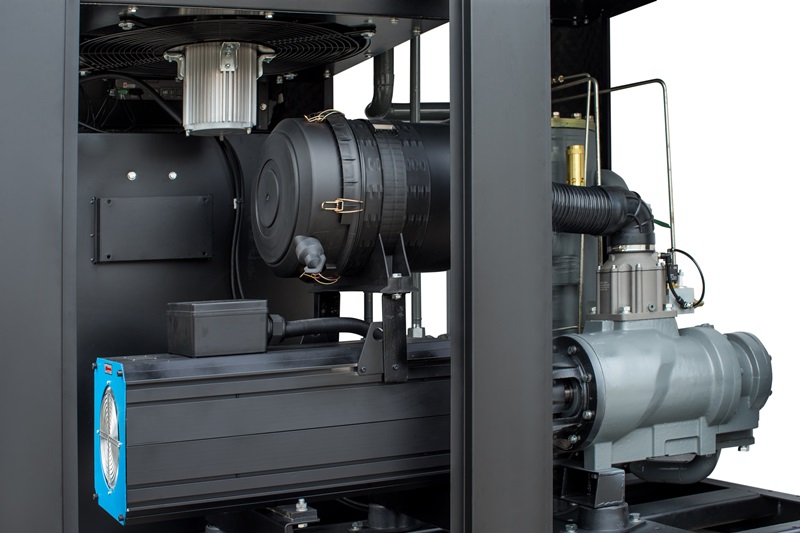

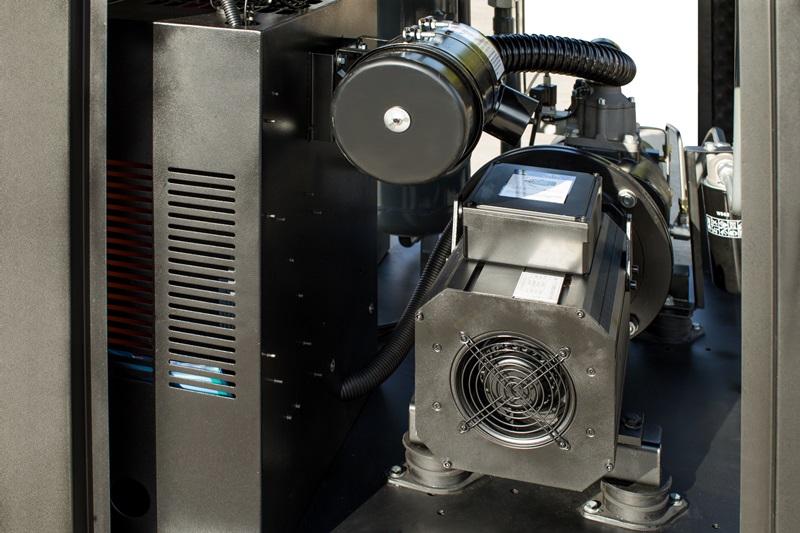

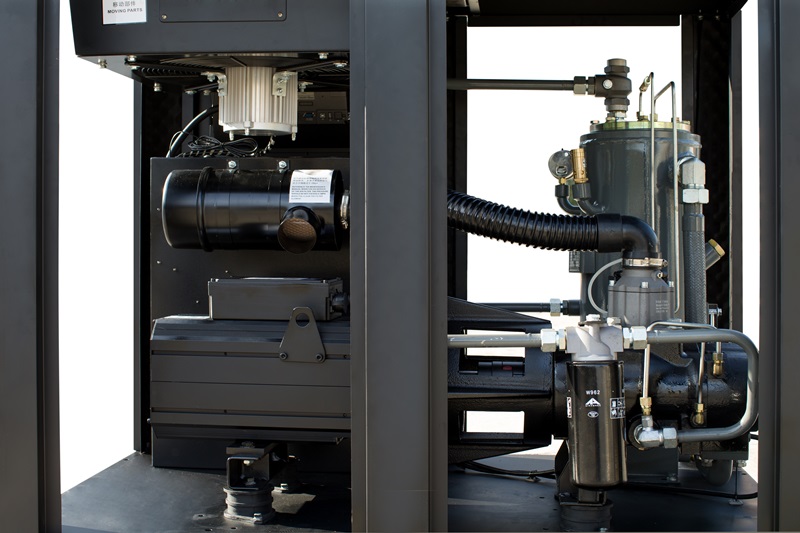

Inler screw host

Large rotors ,low rpm,long life span,High efficiency,low noise,low

vibration,high reliability,Bearings life over 100,00 hours, Little leakage

triangle ,low power/airflow ratio,Less

Plate-fin Cooler

The radiator adopts the high efficiency plate fin structure,heat

exchange,lubricating oil adopt double flow,compressed air adopt single

process,heat balance margin is big,can adapt to worse running condition.

Air oil separator

Large margin design,multi-stage separation Long service life the oil content of

less than 3ppm Ensuring excellent air supply Made from imported glass fabric

Less pollution,Less maintenance.

Multifunctional touch screen

High resolution display,the panel is more clear,rational layout,air compressor

operation date checking more convenient.The ARM processor,mass storage,make the

Communication more efficient.

The unit separation design

Screw machine master for split design, convenient head seal replacement and

motor

The comparison between servo

inverter compressor , inverter

compressor and screw air

compressor without inverter.

A 90kw, Energy Efficiency (0.8Mpa international specific power is 7.3, ?0.7MPA

The motor energy efficiency remains unchanged, the specific power is 6.8) ( Max

pressure is 0.8Mpa, unloading pressure 0.7Mpa) air-cooled compressor Customer’s

actual air consumption: (Assumption) input power 90KW ÷7.3KW/M3×70%=8.63Nm3

AirHorse servo inverter screw air compressor: According to the actual

displacement demand, Constant pressure 0.70Mpa, Required power = displacement

8.63Nm3*specific power 6.8KW/M3=58.68KW Normal inverter compressor: The average

actual input power per minute: (Load power: 90KW*70%=63kw)+(unloading

power:90KW*30%*0.45=12.1KW)=75.1KW screw air compressor without inverter : The

average actual input Compare inverter compressor, the servo ?inverter compressor

saving more energy power: 75.1kw-58.68kw=16.4kw /hour The servo inverter

compressor is 20% higher effectiveness than Inverter compressor. Compare screw

air compressor without inverter, the servo ?inverter compressor saving more

energy power: 99KW -58.68KW = 40.3KW The servo inverter compressor is 40% higher

effectiveness than screw air compressor without inverter

If each machine is working 14 hours a day, working 240 days a year, energy power

cost USD 0.19 /degree Compare screw compressor without inverter, the servo

inverter compressor saving energy power cost: 40.3*14*240*USD 0.19= USD 25727.00

Compare inverter compressor, the servo inverter compressor saving energy power

cost: 16.4*14*240*USD0.19=USD10469.00 Permanent Magnet Inverter Screw

Air Compressor

Model Max working pressure FAD Motor power Unit weight Physical size The

outlet size Moter shell materia

L*W*H

Mpa PSI m3/min CFM KW HP kg mm

APM-20A 0.8 116 2.30 81 15 20 235 970*730*1050 1*3/4″ 铝Aluminum

1 145 2.00 71 245

1.3 188.5 2.60 92 260

APM-25A 0.8 116 3.20 113 18.5 25 325 1250*850*1225 1″*1″

1 145 3.00 106

1.25 181.25 2.90 102

APM-30A 0.8 116 3.80 134 22 30 375

1 145 3.60 127

1.25 181.25 3.00 106

APM-50A 0.8 116 6.50 230 37 50 550 1450*1050*1350 1*1 1/4”

1 145 5.70 201

1.25 181.25 5.00 177

APM-60A 0.8 116 7.50 265 45 60 600

1 145 6.80 240

1.25 181.25 6.40 226

APM-75A 0.8 116 10.50 371 55 75 850 2000*1220*1555 1*2”

1 145 8.90 314

1.25 181.25 7.60 269

APM-100A 0.8 116 13.50 477 75 100 1000

1 145 11.50 406

1.25 181.25 10.10 357

APM-120A 0.8 116 16.50 583 90 120 1900 2520*1680*2000 DN65 铁Iron

1 145 13.7 484